RPVO7-CI ( Vertical Openwell)

RPVO7-CI ( Vertical Openwell)

Description

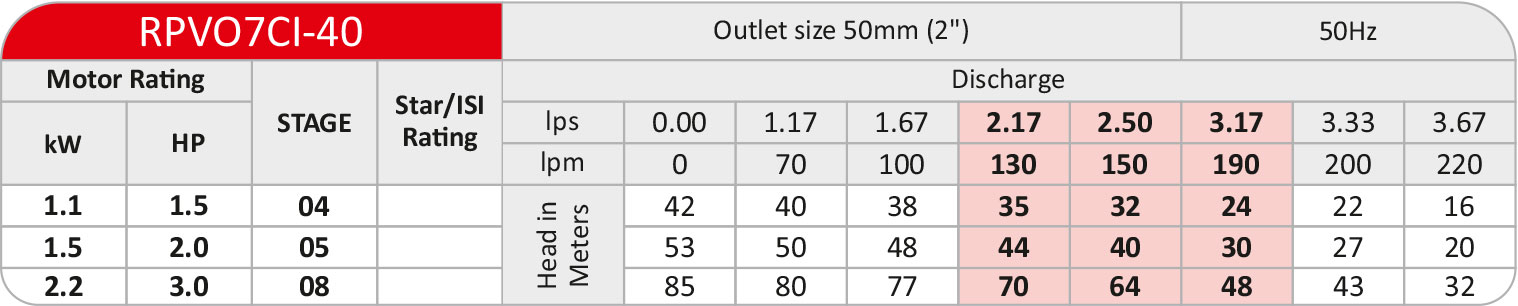

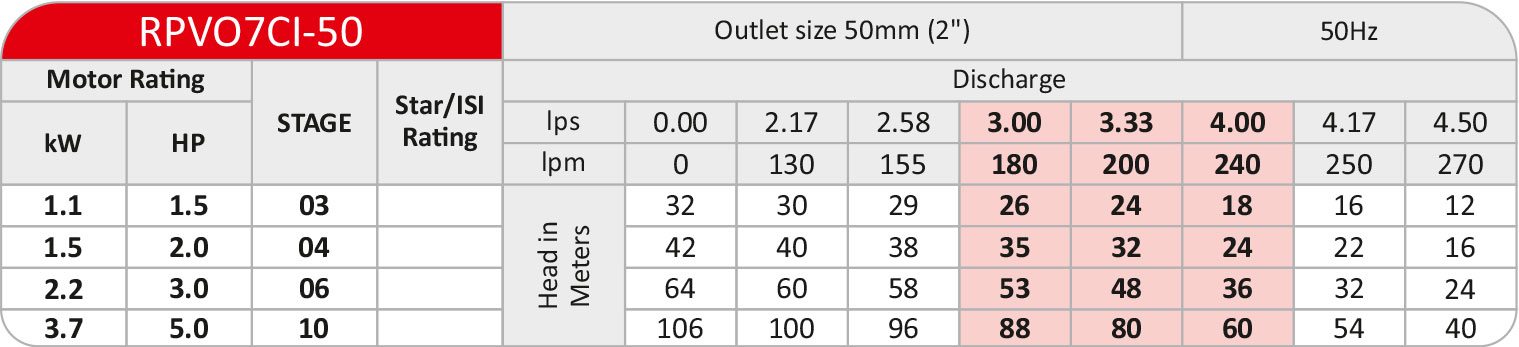

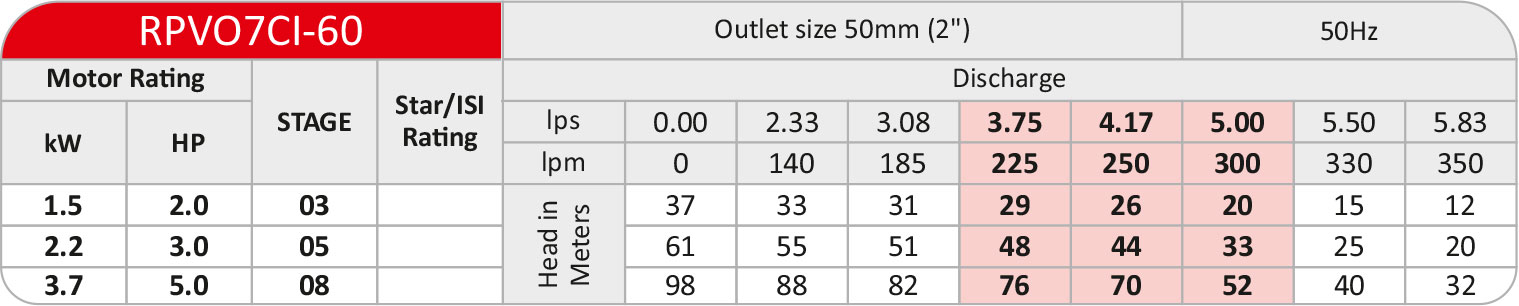

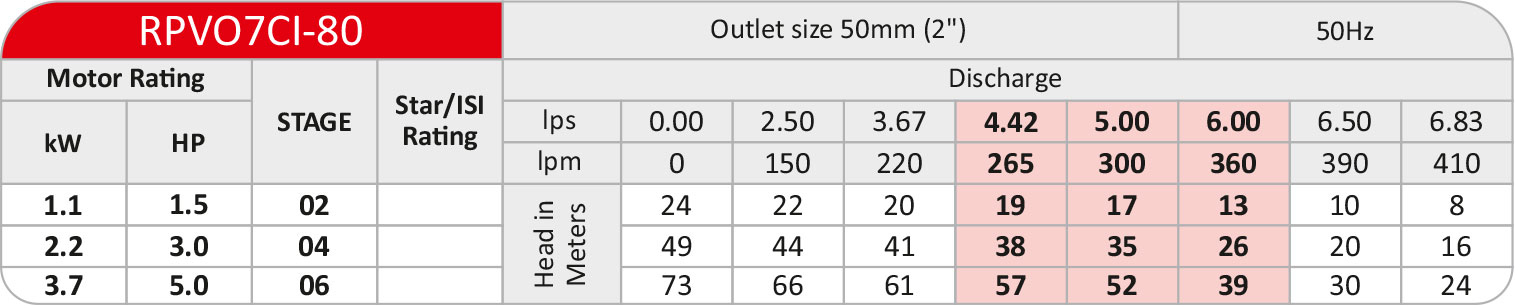

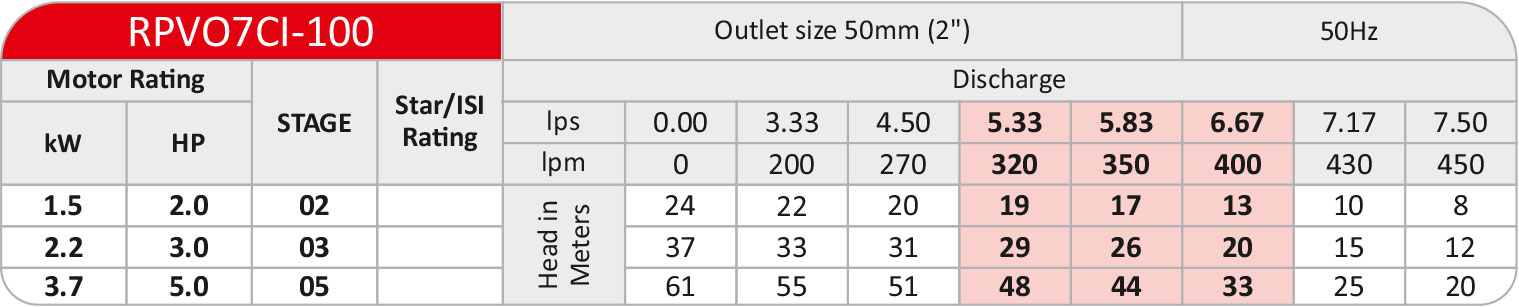

Approx performance chart at 2880rpm, 350 to 420V (T.P.) & 160 to 230V (S.P), 50Hz AC Supply Material Consist; Bowl:Cast Iron & Impeller:SS 410 Maximum Dia.149 mm, Suitable for 150 mm Bore Dia.

Technical Data | |

|---|---|

Power range: | 0.75 to 3.7 kW , 1.0 to 5.0 HP |

Voltage range: | 160 to 240 V, S.P. , 350 to 420 V, T.P. |

Head range: | Upto 106 meter |

Discharge: | Upto 450 lmp |

Rated Speed: | 2880 rpm |

Frequency: | 50 Hz |

Salient Features

- Cast Iron Stator body provides robust design.

- Dynamically Balanced Rotating parts to ensure minimum noise and vibration-free operation.

- Accurately machined on CNC machine to get reliable performance and long life.

- Pump sets perform in wide voltage band.

- Stator and rotor monoset are vacuum impregnated with synthe

- All pump sets are fully tested prior to dispatch.

- Products are available with NRV which reduces the thrust load of back pressure.

- Highly efficient hydraulic design.

- Provided with double eye bolt for easy installation.

- Tough motor base design gives shock absorbing capacity during installation.

Materials Used For Construction :

Motor Details

Type | Descripstion |

|---|---|

Stator | Insulated varnish using vacuum impregnation method |

Rotor | Copper Rotor/Aluminum pressure die-cast |

Motor Body | Stainless Steel/Heavy Duty Cast Iron |

Journal Bearings | LTB-4 |

Thrust Bearing | SS Carbon Thrust Bearing |

Winding | Multi-Layer PVC Insulated wire |

Cable Sealing Arrangement | Nitrile rubber bush locking to protect any foreign particle entering the motor |

Pump Details

Type | Descripstion |

|---|---|

Bowl | Stainless Steel / Cast Iron |

Impeller | Stainless Steel |

Shift | Chrome steel |

Wearing Rings | High Quality Abrasion Resistant Nitrile Rubber |

Suction Rings | Heavy Duty casting material to get proper grip on motor as well as provide path for suction of water. SS Strainer is also providedto protect against foreign particles. |

Non Return Valve | FG 260 to reduce the thrust generated due to back pressure of long pipe line at the time of switch off hence ensuring increase in the life of pump. |

Products Application

Domestic

Goverment

Agriculture

Industrial