RP4GPRF (Radial Flow)

RP4GPRF (Radial Flow)

Description

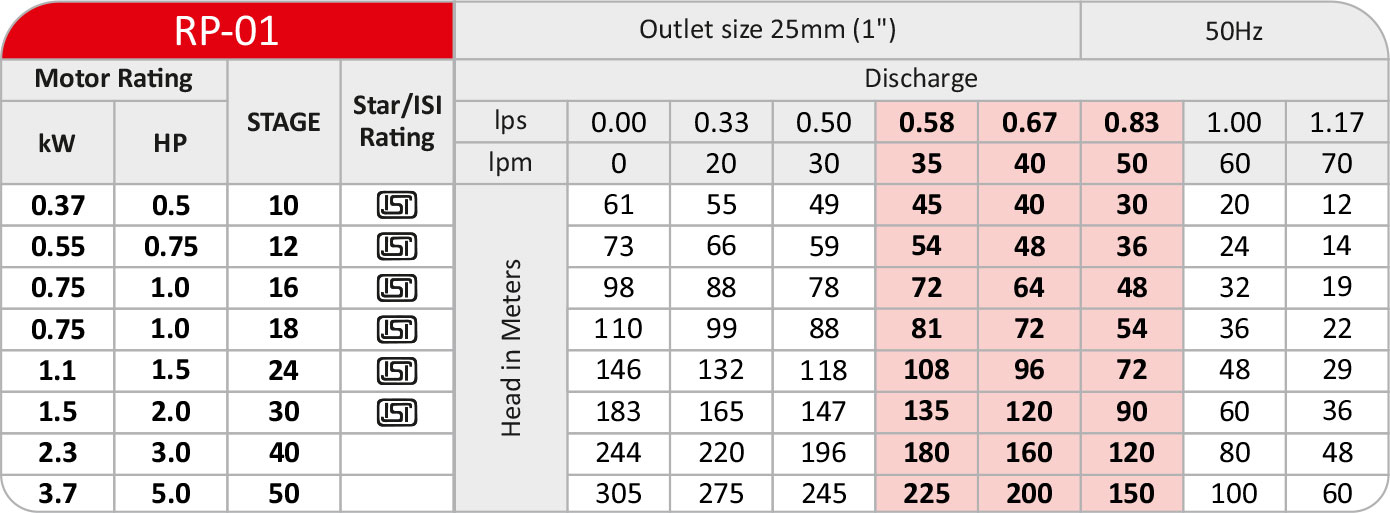

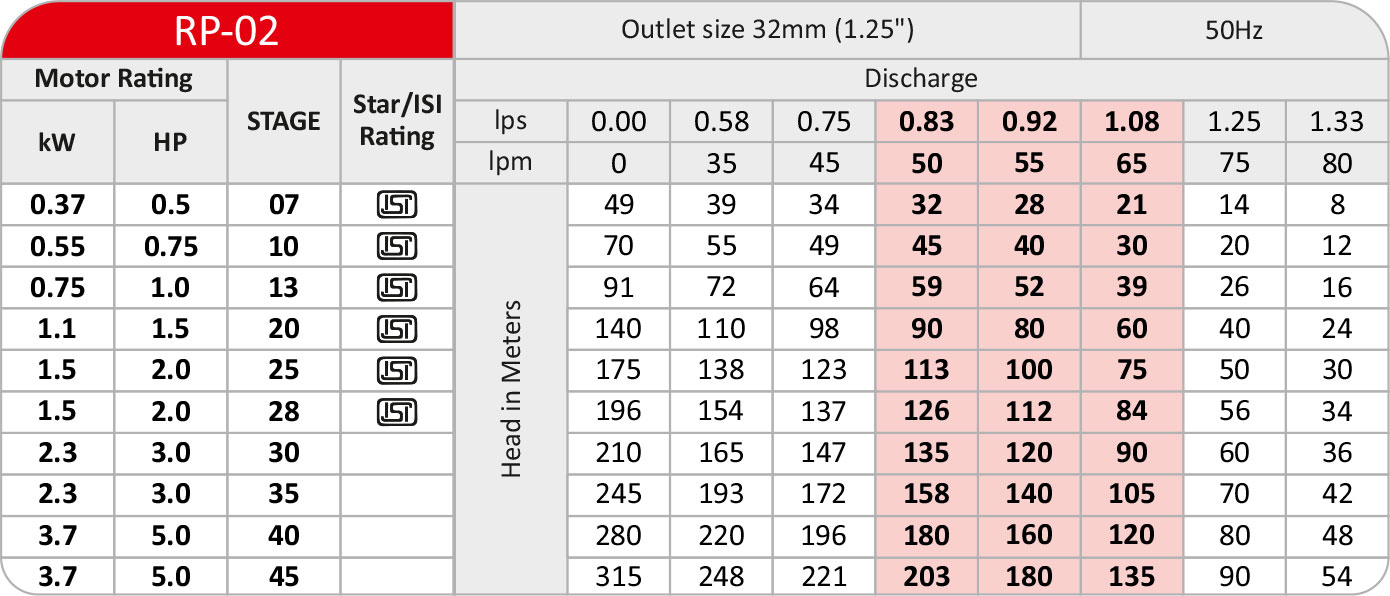

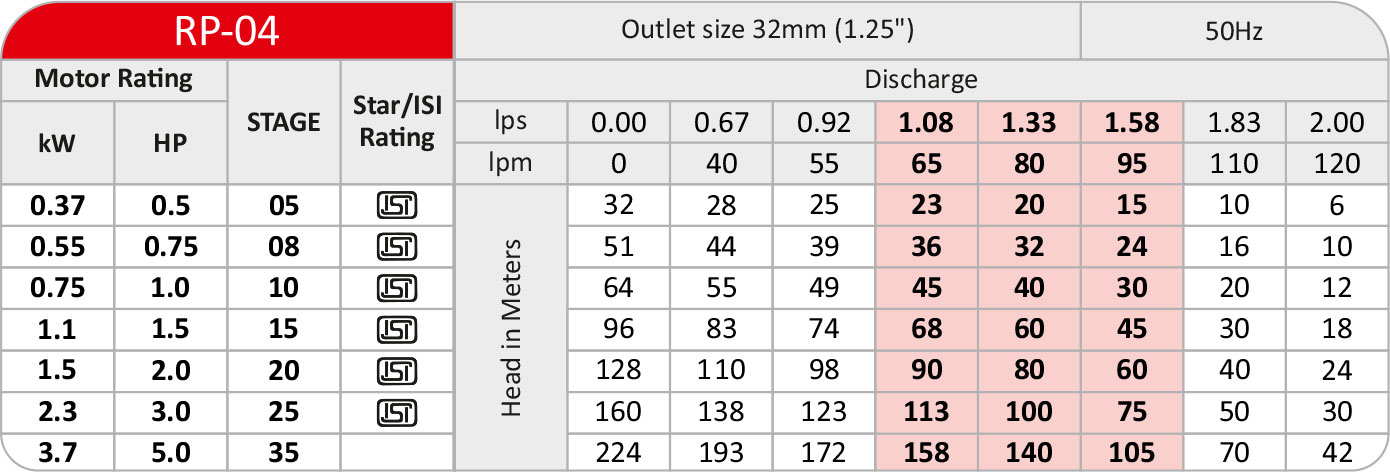

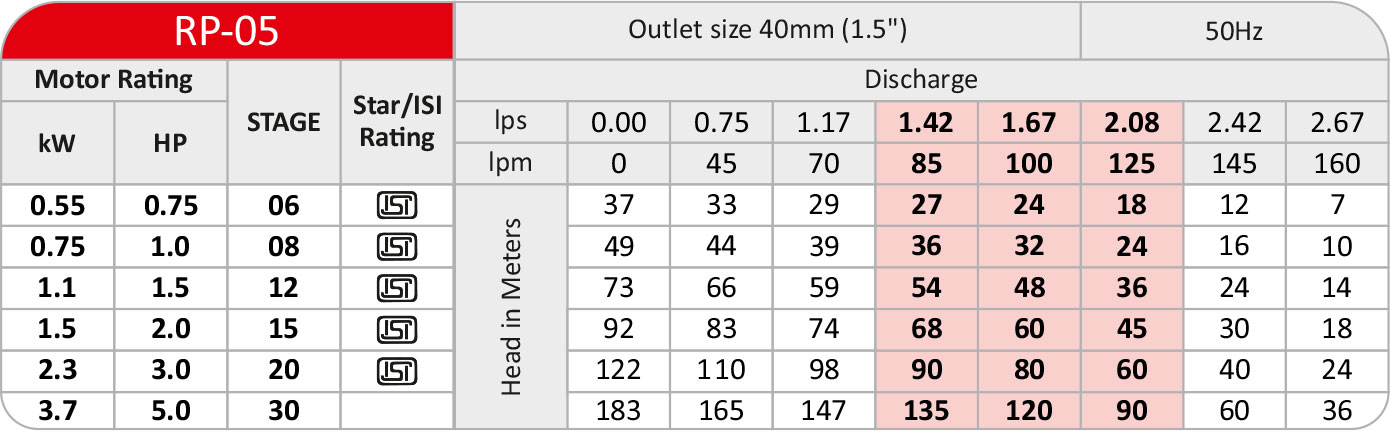

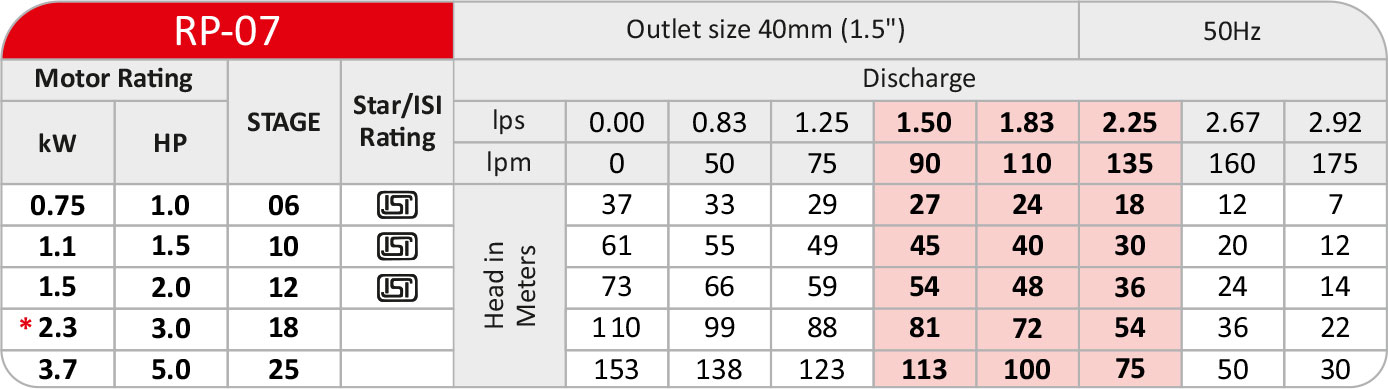

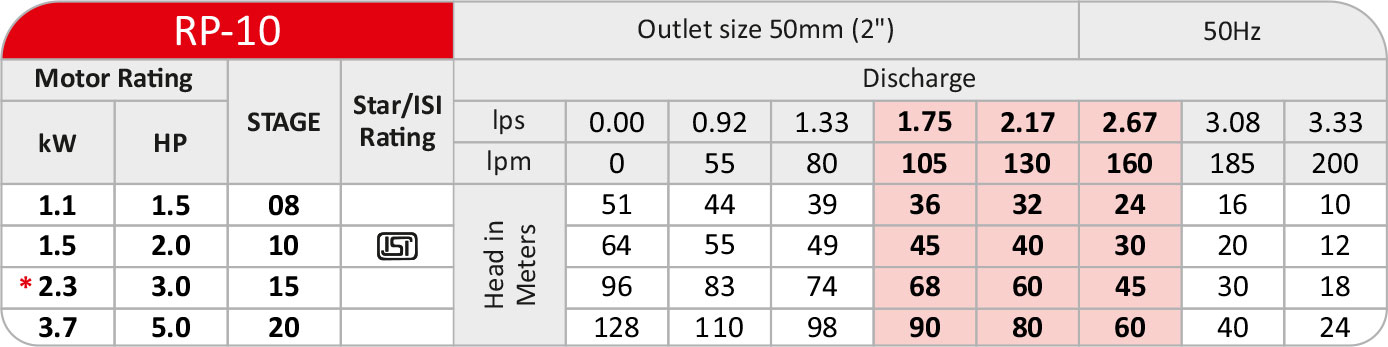

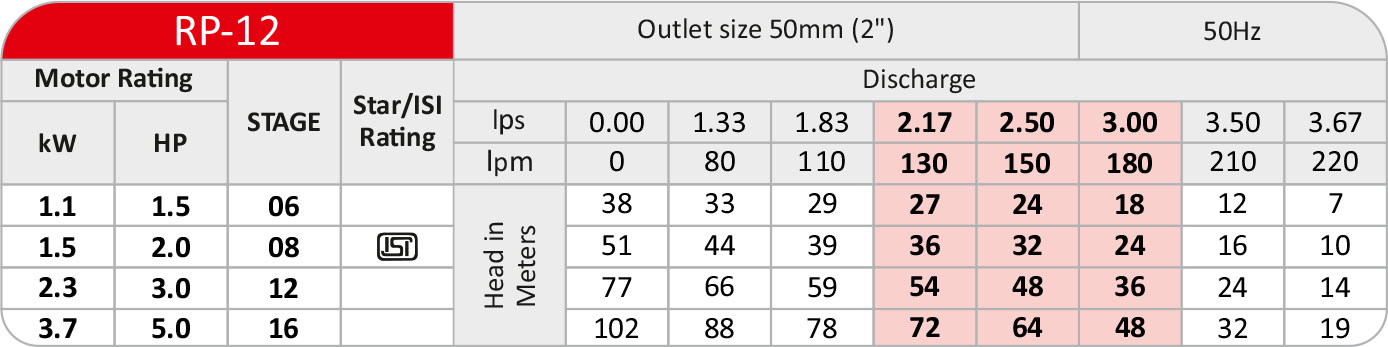

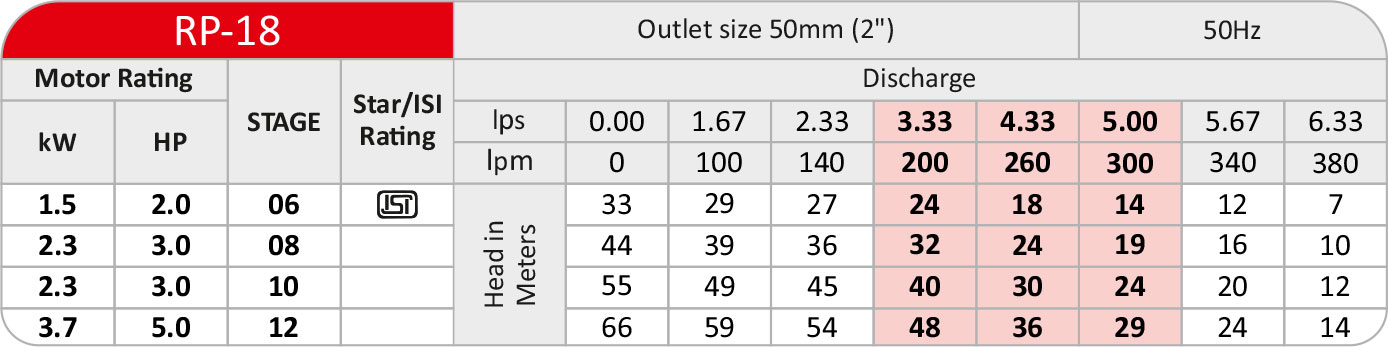

Approx performance chart at 2880rpm, 350 to 420V (T.P.) & 160 to 230V (S.P),50Hz AC Supply Material Consist; Bowl & Impeller: Noryl GFN3,Rotor:Copper

Maximum Motor OD:98mm & Pump OD:96mm

Technical Data | |

|---|---|

Power range: | 0.37 to 3.7 kW , 0.5 to 5.0 HP |

Voltage range: | 160 to 240 V, S.P. , 350 to 420 V, T.P. |

Head range: | Upto 315 meter |

Discharge: | Upto 380 lmp |

Rated Speed: | 2880 rpm |

Frequency: | 50 Hz |

Salient Features

- Dynamically Balanced Rotating parts to ensure minimum noise and vibration-free operation.

- Motor are designed using multi-layer PVC insulated wire to get better for reliability and easy repairing at remote location.

- Pump sets are compact and weight less for easy installation and long life.

- Accurately machined on CNC machine to get reliable performance and long life.

- Pump sets perform in wide voltage band.

- Motor to be filled with water to get better cooling, winding and bush.

- Starts easily at low voltage.

- Manufactured using a much sophisticated hence ensuring more reliability in performance.

- Heavy Duty Carbon thrust bearing with German Technology.

- Products are available with NRV which reduces the thrust load of back pressure.

- Impeller and bowl are made from glass filled noryl that give strong resistance again sand.

Materials Used For Construction :

Motor Details

Type | Descripstion |

|---|---|

Stator | CRNO M45 Grade Stamping Insulated varnish using vacuum Impregnation method |

Rotor | Copper Rotor/Aluminum pressure die-cast |

Motor Body | Stainless Steel |

Journal Bearings | Gun Metal Bush with 2% nickel and additional centrifugal molding |

Thrust Bearing | Self aligned carbon vs. stainless steel thrust bearing that withstand high axial thrust load in water lubrication. |

Winding | Multi-Layer PVC insulated wire |

Cable Sealing Arrangement | Nitrile rubber bush locking to protect any foreign Particles entering the motor |

Pressure Diaphragm | process to avoid chance of warm out Sufficient size to contain expansion of water inside the diaphragm motor and avoid the defeat of cooling water |

Pump Details

Type | Descripstion |

|---|---|

Bowl | Noryl GFN:3 / Cast Iron |

Impeller | Noryl GFN:3 |

Shift | Chrome steel |

Wearing Rings | High Quality Abrasion Resistant Stainless Steel |

Suction Casing | Heavy Duty casting material to get proper grip on motor as well as provide path for suction of water. SS strainer is also provided for protection against foreign particles |

Seal | Carbon ceramic seal |

Non Return Valve | FG 260 to reduce the thrust generated due to back pressure of long pipe line at the time of switch off hence leading increase in the life of pump. |

Products Application

Domestic

Goverment

Agriculture

Industrial