Infrastructure

Manufacturing

Rotec Submersible pumps have a spread across 70,510 Sq. Feet unique infrastructure in place which allows us to meet ever changing market demands, whilst still delivering quality products in high volumes. we have used single flow manufacturing process in our production system to achieve high production rate. We applied LEAN manufacturing process for relentlessly work on eliminating waste from the manufacturing process.

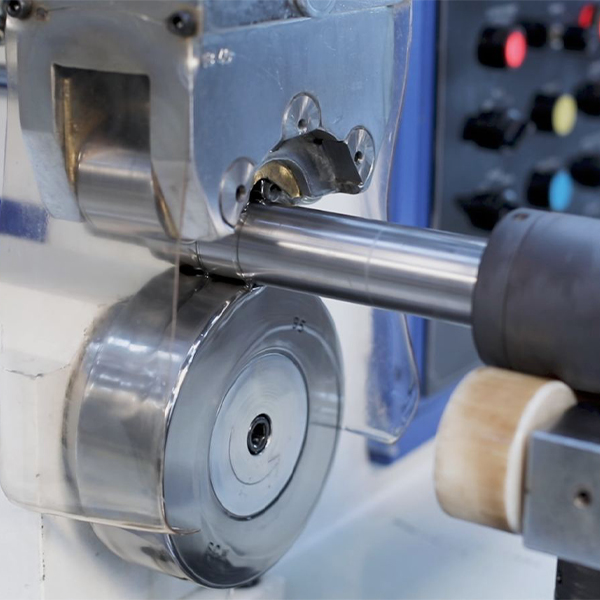

We have Adequate Modern Machines for better Quality products such As: CNC Machines & Lathe Machines for turning Purposes, Different Type Of Press Machines purpose to Rotor-Stator Press, Bearing Bush press etc., Grinding Machine for Rotor Grinding , In-house Brazing Machine With cooling Tower, Automatic Balancing Machine for precise Rotor Balancing, Key-way Machine, Drill Machines, Vacuum Varnish Machine for Stator varnish, Growler Machine for check Blow Hole in Aluminum Die cast, Pipe Bending and Groove Machines, laser marking, HV Tester, computerized Testing facility, Automatic color booth, Argon Welding, Burnishing Machine etc.

Manufacturing facilities

Rotec Submersible pumps have a spread across 70,510 Sq. Feet unique infrastructure in place which allows us to meet ever changing market demands, whilst still delivering quality products in high volumes. we have used single flow manufacturing process in our production system to achieve high production rate. We applied LEAN manufacturing process for relentlessly work on eliminating waste from the manufacturing process.

We have Adequate Modern Machines for better Quality products such As: CNC Machines & Lathe Machines for turning Purposes, Different Type Of Press Machines purpose to Rotor-Stator Press, Bearing Bush press etc., Grinding Machine for Rotor Grinding , In-house Brazing Machine With cooling Tower, Automatic Balancing Machine for precise Rotor Balancing, Key-way Machine, Drill Machines, Vacuum Varnish Machine for Stator varnish, Growler Machine for check Blow Hole in Aluminum Die cast, Pipe Bending and Groove Machines, laser marking, HV Tester, computerized Testing facility, Automatic color booth etc.

Also we have crane facilities in testing area and plant area to damage free material handling & In every Assembly area we have putted pressured Air point to use Air Gun, fastener tighter, blower, Color spray etc various purpose.

We have a dedicated assembly area for our sub-assembly process with a skilled and qualified team. Dust free Assembly area to ensure manufacturing of products with quality Computerized accounting & administrative facilities are created for smooth & efficient working so that customer satisfaction can be maximized.